Description

Focus Area: Additive Manufacturing / Advanced Manufacturing

Estimated Budget Range: TBD

Submission Deadline: Thursday, December 31st, 2026 at 00:00, ET

SUMMARY

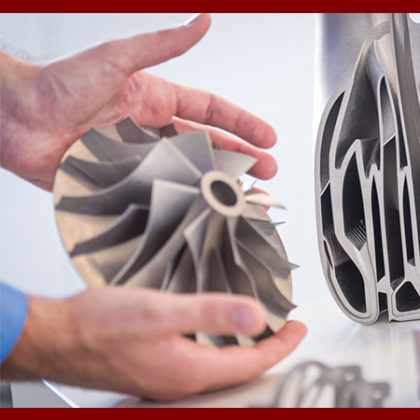

There is an urgent need for rapidly deployable advanced manufacturing concepts that can significantly improve Supply Chain Management (SCM) sustainment and asset availability. Three-dimensional (3D) printing technology has the potential to revolutionize parts availability and has recently experienced rapid advancements in both quality and speed of production. Specifically, additive manufacturing offers an unprecedented opportunity to mitigate diminished manufacturing sources of supply and long supply chain lead times, while enabling operational agility and increasing the lifespan of legacy systems.

Patriot Labs is interested in additive manufacturing methods that support accelerated delivery of on-time/on-schedule parts for both prototype systems development and fielded direct replacement parts. Proposed approaches should be capable of accurately recreating 3D printed parts using existing Technical Data Packages, as well as rapid part reverse engineering from hands-free scanning.

For purposes of this CFI, solutions should employ approaches that optimize part design, use fewer materials, and produce parts more quickly without compromising durability or quality. Desired benefits include better performing, more cost effective, and more reliable technology to produce the parts required to ensure sustained operability of fielded assets thereby reducing the risk of obsolete hardware.

Approaches could also include techniques that result in reduced material waste, increased production flexibility, and the ability to decentralize production. Special consideration given to advanced manufacturing techniques that produce parts from titanium, aluminum, polymer, or hybrid materials. The ability to combine parts, blend materials, create innovative lightweight structures, and build internal features is considered advantageous. Solution providers must be prepared to rigorously demonstrate their production methods in order to attain manufacturing certification and support the approval of any newly proposed materials, processes, and components.